- Gloveboxes

Gloveboxes

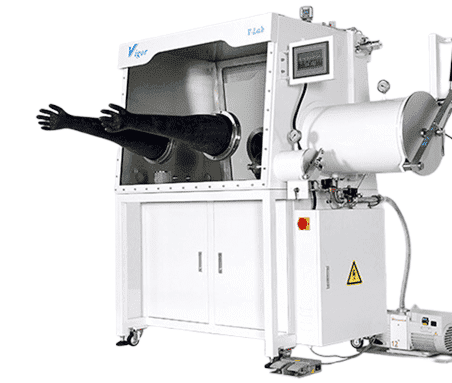

- Vigor Gloveboxes

Vigor Gloveboxes

- Standard gloveboxes

- Cleanroom Gloveboxes

- Pompen

Pompen

- Diffusiepompen

Diffusiepompen

- Diffstak serie

- nHT serie

- Semiconductor pompen

- Multiroots vacuümpompen

Multiroots vacuümpompen

- nXR serie

- Industriële pompen

Industriële pompen

- GXS serie

- Industriële serie

- Atex serie

- Droogpompen

- UHV pompen

UHV pompen

- HyTan

- IGP

- Digital controller

- NEG

- TSP

- Cryopompen

Cryopompen

- Waterpumps

- OnBoard

- Compressors

- Cryotorr

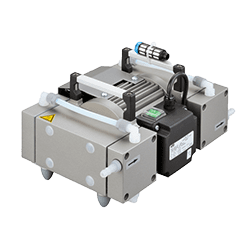

- Membraanpompen

Membraanpompen

- MPC serie

- Atex serie

- D-lab serie

- LVS serie

- RV vacuümpompen

RV vacuümpompen

- RV serie

- EM Vacuümpompen

EM Vacuümpompen

- E2M serie

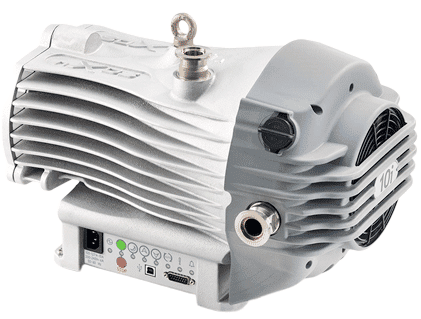

- nXDS Scrollpompen

nXDS Scrollpompen

- nXDS serie

- XDS serie

- Turbopompen

Turbopompen

- STPiS serie

- STPiX serie

- nEXT serie

- Toebehoren

Toebehoren

- Vacuümolie

Vacuümolie

- Ultragrade performance vacuum olie

- Spares

Spares

- Spares

- Instrumentatie

Instrumentatie

- AIM200 serie

- Barocel serie

- APG200 serie

- WRG200 serie

- Specials

- Documentatie

Meer informatie over

Acclon Technologies

Acclon Technologies levert innoverende en geavanceerde producten op het gebied van vacuümtechniek. Wij zijn dé professional voor vacuumpompen en gloveboxen. Of het nu gaat om de aanschaf van een enkele vacuümpomp of een complex hoogvacuüm probleem, wij helpen u graag. Doordat wij onafhankelijk werken, zijn wij altijd in staat om het beste advies te geven. We werken in een hecht en goed geolied team dat altijd voor elkaar klaarstaat, vanuit ons kantoor in Heinenoord. Elke dag weer zijn we bezig om de puzzels van onze klanten op te lossen.

25+

Jaar in-house

ervaring

2000+

Producten

op voorraad

15

Medewerkers

in dienst

1500+

Tevreden klanten

ontzorgt

Een overzicht van onze

Product categorieën

Als professional voor vacuumpompen en gloveboxen bedienen wij

De volgende markten

Research & Development

Vacuüm vormt in veel gevallen het hart van research & development. Of het nu gaat om het creëren van vacuümcondities voor het uitvoeren van gevoelige experimenten of het faciliteren van complexe productontwikkeling, vacuümpompen bieden een betrouwbare en efficiënte oplossing.

Lees verder

Chemie & Voeding

U kunt op ons, als professional voor vacuumpompen rekenen. Onze vacuümsystemen (van onder andere Edwards Vacuum) kunnen een belangrijke rol spelen bij het verhogen van de productkwaliteit en winstgevendheid met nieuwe niveaus van betrouwbaarheid, flexibiliteit en kosteneffectiviteit.

Lees verder

Machinebouw

Bij Acclon Technologies begrijpen we de steeds veranderende uitdagingen op het gebied van analytische instrumentatie. Door deze kennis en onze uitgebreide ervaring in het werken met toonaangevende OEM’s hebben wij hoogwaardige vacuümpompen en controllers in ons assortiment voor schone en betrouwbare vacuümomgevingen.

Lees verder

Industrie

Onze producten zijn ontworpen om u te helpen procesbesparingen op lange termijn te realiseren en een duurzame bedrijfsvoering te ontwikkelen. De innovatieve technologieën die we hebben ontwikkeld, hebben geholpen het gebruik van vacuüm voor industriële toepassingen te bevorderen, de kapitaalkosten te verlagen, de bedrijfsefficiëntie te verbeteren en de impact op het milieu te verminderen.

Lees verderSemiconductor

De uitdagingen van prestaties, veiligheid en naleving van milieuvoorschriften kunnen ontmoedigend zijn. Onze wereldwijde leidende positie in vacuüm- en gasverwerking voor de fabricage van halfgeleiders is gebaseerd op onze know-how door ervaring, informatie en gegevens, die gedurende tientallen jaren zijn verzameld.

Lees verder

Energie

Ons pionierswerk voor de energie-industrie bij de ontwikkeling van apparatuur voor vroege energiecentrales is de basis geweest voor onze huidige leidende positie op de markt. Vandaag de dag leveren we geavanceerde vacuümsystemen voor thermische, nucleaire en zelfs zonne-energiecentrales. We zijn in staat om de grenzen van het ontwerp van vacuümsystemen te verleggen om te voldoen aan uw specifieke eisen voor energieopwekking.

Lees verder